Proactive Geosteering in SAGD / CSS Heavy Oil Sands

Alberta’s oil sands are among the world’s largest deposits of crude oil – in fact, there are more than 1.8 trillion barrels of bitumen in the ground, According to the Alberta Energy Regulator (AER).

Oil sands are a mixture of sand, clay, water, and bitumen. Bitumen is extra-heavy crude oil, some of which is so viscous that it cannot flow on its own. About 80 percent of the recoverable bitumen reserves in Alberta are buried too deep to mine and can only be recovered by drilling wells. This is referred to as ‘in situ’ recovery, according to the AER. Steam is injected to reduce the viscosity so the well can flow.

There are two main thermal in situ oil sands technologies:

- Steam-assisted gravity drainage (SAGD), and

- Cyclic steam stimulation (CSS) also known as ‘huff and puff’

Geosteering Objective:

The geosteering objective was to optimize the wellbore position 1m above the reservoir base while maintaining a smooth wellbore profile without tagging shale below.

Challenges:

- The sub-seismic uncertainty in geological surfaces coupled with directional surveys frequency that increase cone of error with lateral extension.

- Bit deflection due to stringers.

- If penetrate shale or drilling above zone, for certain footage, sidetrack was required.

Geosteering Summary:

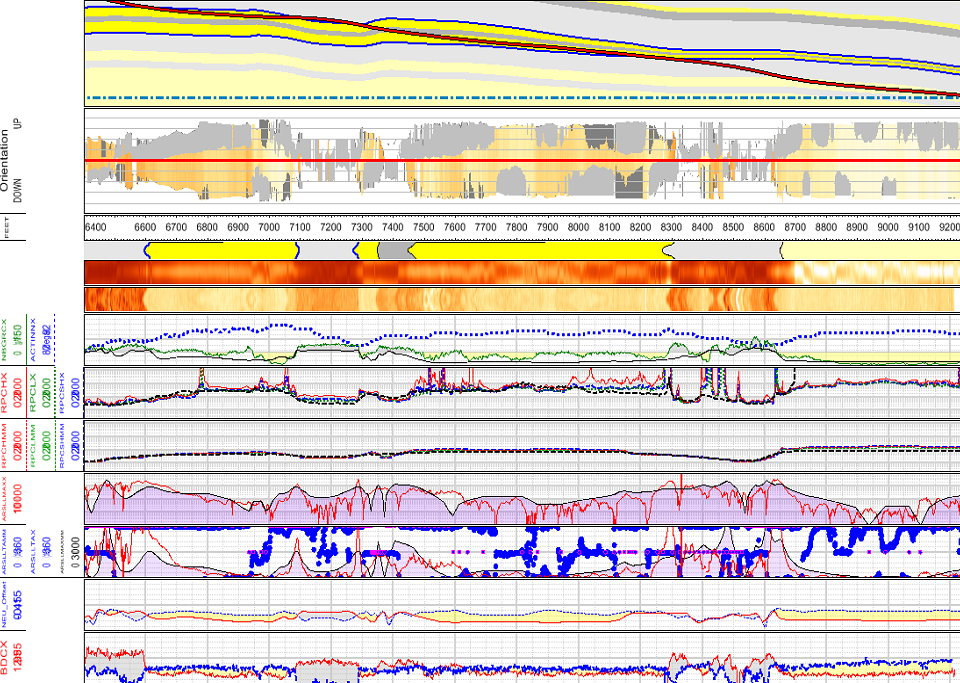

The well was geosteered remotely utilizing the gamma ray and resistivity tools in the drilling BHA. The gamma ray was 13m behind the bit with 6-9 inches depth of investigation. The bulk gamma ray was utilized for the confirmation of shale tags. The deep azimuthal resistivity tool’s deep and shallow curves were utilized to geosteer the well proactively without penetrating shale while optimizing the wellbore position within the target interval. The resistivity tool was 17m behind the bit with depth of investigation ~1m inside the formation.

The well was maximized in the formation utilizing the bed boundary effects on wave propagation resistivity. A criterion was developed to recognize resistivity curves responses on stringers and at shale approaches. The confirmation of reservoir base was done successfully at various depths without penetrating shale below.

The wellbore was placed smoothly 100 percent in target zone, achieving the well objectives.

The post well analysis was done after receiving tool’s memory data utilizing more than 150 data curves for detailed analysis and conclusions.

Conclusion:

- Knowledgeable personnel (Geosteering specialists)

- Experts with in-depth knowledge of most recent LWD tools and directional drilling technology

- Extensive knowledge of geological and drilling operations.

- Team-work

- Effective communications

- Nunc felis. Curabitur ac ipsum. Pellentesque nibh ultricies est. Maecenas consequat, augue a venenatis risus. Ut id mollis vel, lacinia quam.

- Pellentesque et lacus pretium tincidunt. Pellentesque at metus. Donec nisl a nisl. Vestibulum ante ipsum primis in nulla orci.

- Vivamus ullamcorper orci quis lectus elit, dictum aliquet at, egestas ac, felis. Quisque eu sem condimentum enim ut congue risus.

- Vestibulum ante ipsum primis in metus. Curabitur nec ante. Donec congue. Integer adipiscing. Nunc placerat eget, bibendum nulla.

- Etiam in augue. Nulla facilisi. Morbi felis tincidunt eget, faucibus orci nec erat a quam placerat vehicula neque.